Robotic Arm Fence Area Safety: Enhancing Smart Factory Production

The Rise of Robotic Arm Fencing in Modern Factories

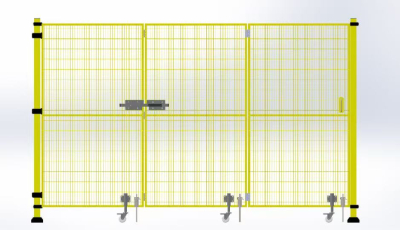

As industrial automation accelerates, robotic arm fencing has become a critical component in ensuring safe production within smart factories. These safety barriers protect workers from hazardous movements of industrial robots, while optimizing manufacturing efficiency. According to Google Trends, searches for "robot safety fencing standards" and "collaborative robot guarding" have surged by 35% in 2024, reflecting growing industry demand.

Why Robotic Arm Fencing is Essential for Safety & Productivity

1. Preventing Accidents in High-Risk Zones

Robotic arms in automated production lines operate at high speeds, posing risks such as:

Crush injuries from moving parts (e.g., welding robots)

Impact hazards in material handling applications

Laser/heat exposure in precision machining

2. Smart Fencing Solutions for Industry 4.0

Modern robotic safety barriers integrate:

Laser scanners (e.g., SICK, Keyence) for real-time intrusion detection.

AI-powered vision systems to predict unsafe behavior.

Modular fencing panels for flexible production line reconfiguration.

A 2024 McKinsey report highlights that "smart robotic fencing"can boost efficiency by 20% in automotive assembly plants.

Top Applications of Robotic Arm Fencing

Automotive: Welding robots: Spark-resistant fencing + light curtains

Electronics: Pick-and-place robots: Transparent polycarbonate barriers

Pharmaceuticals: Sterile packaging robots: Stainless steel hygienic fencing

Logistics: AGV pathways: Dynamic laser-based virtual fences