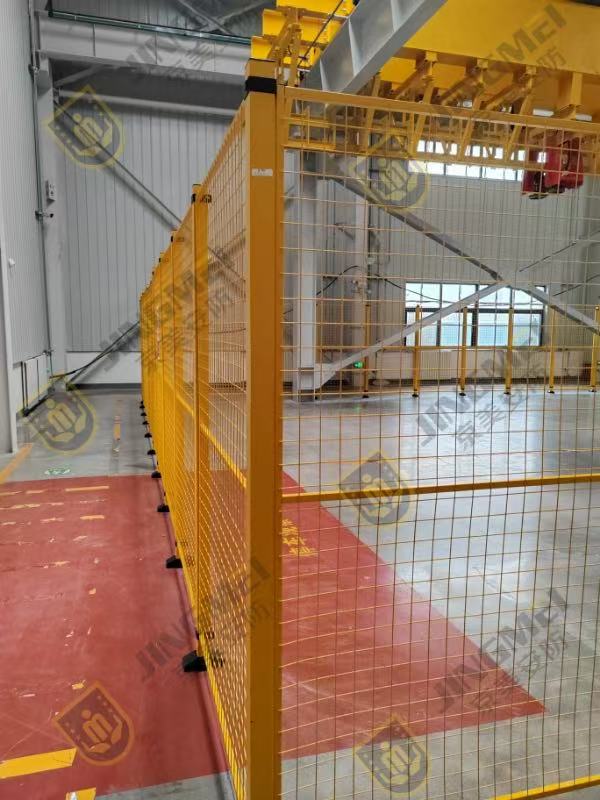

Robotic fencing in factory

Safety: Isolate hazardous areas through physical/electronic fences to prevent personnel from entering the working range of robots or automated equipment and avoid

Collision Injuries: safety fence for automation are equipped with laser radar and infrared sensors to monitor intrusions in real time and trigger emergency stops.

Efficiency improvement: Reduce manual intervention, ensure production continuity

Collaborate with AGV (Automated Guided Vehicle), robotic arms, and other equipment to optimize logistics routes.

Flexibility and Scalability: Modular design allows for quick adjustment of access safety fencing range and height based on factory layout.

Product introduction

Robot fence refers to a safety protection system used in factory automation production environments, aimed at isolating the working area of automation equipment such as robots, robotic arms, AGVs, etc., preventing personnel from entering dangerous areas and ensuring production safety.

Specificatipns

robotic fencing Mesh height: 2000mm

robotic fencing Mesh width: 1000mm

robotic fencing Grid size: 20*100mm

robotic fencing Silk diameter: 3mm

robotic fencing Mesh frame: 20*20mm

Application scenarios

Automobile making: The welding and painting areas of the robotic arm are isolated to prevent sparks from splashing and injuring people or accidentally touching them.

3C electronic assembly: Install gratings around SMT surface mount machines and precision assembly lines to ensure safe operation of high-speed equipment.

Logistics warehousing: The AGV channel and manual picking area are divided by electronic fences to avoid forklift collisions.

Metalworking: Security interlocking fences are deployed around stamping machines and CNC machine tools, with automatic power-off upon opening the door.