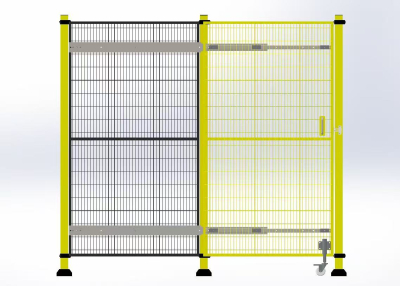

Industrial Standard Fence Railing

Industrial standard railings refer to railing facilities set in industrial environments to ensure personnel safety, prevent falls, divide areas, etc., and comply with relevant national standards and industry specifications.

Industrial railings, with their exceptional durability and reliability, have become key facilities for ensuring production safety. They are meticulously manufactured from high-strength special materials, capable of maintaining stable performance in complex working conditions such as high temperatures and high humidity, as well as in high-frequency usage scenarios. Their sturdy structural design forms a safety barrier, effectively preventing unauthorized personnel from entering dangerous areas and significantly enhancing the safety factor of workplaces.

In terms of practicality, industrial railings combine convenience and flexibility. Their installation process is simple and efficient, with low daily maintenance costs, and they can be freely customized in length and style according to the needs of different industrial scenarios. Thanks to special surface treatment processes, industrial railings have excellent corrosion resistance and can serve stably for a long time in diverse industrial environments such as chemical plants, warehouse logistics areas, and automated production lines. In addition, the modular design gives them strong scalability, enabling easy adaptation to dynamic adjustments in industrial layouts. Through simple assembly and reconfiguration, they can quickly meet the needs of production upgrades.

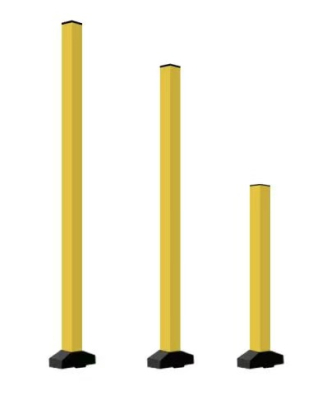

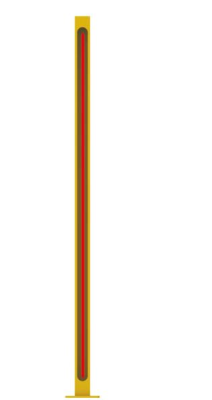

Industrial railings are composed of yellow and black circular pipes, and include polymer anti-collision strips, shelf anti-collision sleeves, building column protective barrels, and corner warning lights.

Polymer anti-collision strips: Installed at the bottom of railings or easily collision-prone parts, made of elastic polymer materials to buffer impact force and reduce damage to equipment or personnel.

Shelf anti-collision sleeves: Wrapped around the bottom of shelf columns to prevent forklifts or handling equipment from colliding with shelves and causing them to tip over.