Mechanical bending machine

Superior Stability and Rigidity: The CNC bending machine features an integral welded bed made of steel plate, offering excellent shock resistance and rigidity.

Stress-Free Frame: The annealing process eliminates stress in the frame, ensuring high stability and preventing deformation.

Energy Efficient and Low Noise: Delivers excellent energy-saving performance, operates at high speed with low noise.

User-Friendly Interface: The automatic bending process interface is simple and easy to learn, reducing the need for extensive operator training.

Automatic Angle Compensation: The machine automatically calculates and compensates for bending angles, ensuring precise results with minimal trial bends.

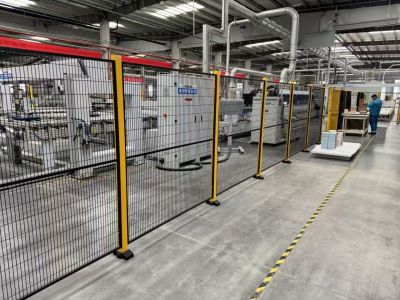

Product Introduction

Pure electric servo bending machine mainly relies on servo motor to drive the ball screw or other transmission devices to achieve the up and down movement of the, so as to complete the bending operation of the metal plate. The servo motor receives the instructions issued by the CNC system, accurately controls the speed, position and torque the motor, so that the slide can move according to the preset trajectory and speed, and achieves high-precision bending processing. For example, when processing the sheet metal of the shell of small electronic devices, through the precise control of the servo motor, the plate can be bent into various complex shapes and angles to meet the design requirements the product.

Specifications

model: ESP60-2500

Controlled Axes: Y1 、Y2、 X、 R、 Z1、 Z2

Dimensions (mm)(length * width * height): 2600*2060*2150

Workbench length(mm): 2500

Bending pressure(KN): 600

Applications

Electronic equipment manufacturing industry

Chassis and cabinet production: The chassis and cabinets of electronic equipment are usually made of metal sheets. bending machines are used to bend the sheets into the various sides and frames of the chassis and cabinets, ensuring that they have good structural strength and appearance quality. At the time, precise bending processes can ensure the dimensional accuracy of the chassis and cabinets, facilitating the installation and wiring of internal electronic components.

Electronic component processing: Some electronic components such as heat sinks and shielding covers, also need to be formed through bending processes. CNC bending machines can perform precise bending processing according to the small size and high precision of electronic components, meeting the performance and quality requirements of electronic equipment for components.

Building and decoration industry

Building curtain wall: In the construction of building curtain walls, sheets need to be bent into various shapes to make the edges, decorative lines, and other parts of the curtain wall. CNC bending machines can precisely bend metal sheets of materials and thicknesses according to the design requirements of the curtain wall, improving the installation accuracy and overall aesthetics of the curtain wall.

Interior decoration: In the field interior decoration, CNC bending machines can be used to process various metal decorative strips, window and door frames, etc. Through precise bending processes, it is possible to make parts with different curvatures and angles, adding unique style and texture to interior decoration.